Rosenbauer MasterControl –

Reduction of operating costs with automated system inspections

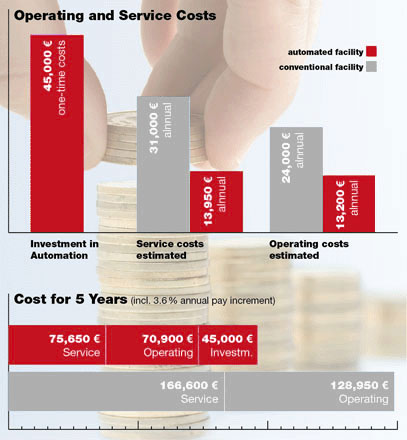

The Rosenbauer MasterControl automation system offers substantial cost savings to plant operators. The operating personnel only operates the central control unit. Time-consuming manual component tests are replaced by automatic routines. Electronic data logging avoids reading errors, saves time and provides secure documentation for the test runs.

There is a return on investment after just a short period of time

Regular checks of fire sprinklers are required according to the VdS and FM guidelines. The control operations are divided into daily, weekly and monthly sections and must be documented in a log book. In particular, the verification of the alarm pressure switches, flow switches and the pumps represents a lot of work, which is significantly reduced by the use of MasterControl automation. This results in cost savings, which pays for the investment costs within a short period of time.

The regular inspections are divided into the daily inspection of the system and regular trial runs of the individual system components.

Fully automatic test runs and documentation

The MasterControl system performs the routines to be tested fully automatically. All test results are documented immediately after the end of the test phases. A built-in printer and the graphical depiction of the sprinkler system is made available in the visualization system.

Via solenoid operated valves, water flow through the alarm valve is simulated and the alarm chain is triggered. The control and documentation are undertaken automatically as per a predetermined sequence via the automation system. By means of parallel assigned valves to the flow switches and circulating pumps, a remote controlled water flow can only be produced by the respective flow detector. The response of the detector is again automatically displayed and documented in the visualization.

In order to assess the pump performance, the recorded pressure and flow values ??are shown by the visualization in graphs and tables and compared with the reference curve.

After completion of the test phase, all individual results are issued by the integrated printer and can be permanently archived according to the documentation policy.

These are the advantages of automated inspection on your sprinkler system with Rosenbauer MasterControl:

MasterControl handles all of the required inspections

Weekly test runs

- Functional testing of the alarm pressure switch (open the individual alarm test valves and triggering the alarm chain).

- Test of the flow detectors for alarm division by parallel manual testing or electrical check zones (water flow using flow detectors, signal transmission to fire panel).

In addition to the weekly test runs

- Control of automatic pump starts and operational readiness of pumps and their drives (during testing, the normal operating parameters of the drive motors can be achieved).

Monthly test runs

- Function control of the automatic refill devices for intermediate, pump fill and elevated tanks.

- Pump test run with target-actual comparison of the pump curve for determining the operational readiness and to control the automatic pump starts.

- Sample function of the mixing system / fittings in systems with foaming agent (no water, no foam).

Quarterly inspections

- Flow detectors should be checked for their function and assignment to the protected area.

- Functional test of the monitoring system (min. one transmitter per monitoring line).

- All shut-off valves that control the flow of water to the sprinklers are to be operated to ensure the operational readiness.

Six-monthly test runs

- Sample function of the mixing system / fittings in systems with foaming agent (with water, no foam).

Annual test runs

- Determine and document the performance data of the sprinkler pump using pump test runs in a characteristic curve* (starting up the operating points of the pump by adjusting the sample slide and determining the values ??for water pressure and flow rate).

* The comparison of the recorded characteristic curve and manufacturer characteristic curve provides information about the condition of the sprinkler pump. The relevant pump will start automatically for implementation. Electrical control valves set the specified flow rates and the corresponding sensors record the pressures. The control valves are usually modified fully digitally by the control unit.

FULL LINE DISTRIBUTOR

IN FIRE PROTECTION

Rosenbauer Fire Protection

provides the full line of

products and services

in the preventative

fire protection business.

BEST ADVICE AND

PROVEN DESIGN

Nearly three decades of

experience in planning and

designing fire protection

systems for all cases of

safety requirements.

IN-HOUSE ENGINEERING

AND ASSEMBLING

Supervision and construc-

tion according to various

safety standards by our

own engineers and

high qualified personnel.

RELIABLE SERVICE

AND MAINTENANCE

Continuous maintenance

by trustworthy partners

is the key to an

unimpeachable preventative

fire protection system.

ALMOST THREE DECADES IN IMPLEMENTING FIRE PROTECTION SYSTEMS

AND STILL ON FIRE FOR IT.

WATER-BASED SYSTEMS

SPRINKLER SYSTEMS

This common type of water-based fire extinguishing system is reliable and easy to implement.

SPRAY DELUGE SYSTEMS

Deluge systems are the first choice in areas with a risk of rapidly spreading fires.

WATER SPRAY SYSTEMS

Water mist already exerts its effect on flames and smoke – for safety of people and assets.GAS-BASED SYSTEMS

CO2 FIRE SYSTEMS

The gas-based extinguishing system with widest acceptance worldwide.

SAFETY INTEGRITY LEVEL 2

Systems certified for risk classes up to SIL 2 – an integral component in security concepts.

NOVEC 1230 SYSTEMS

Reliably and automatic protection for data processing and electronic control systems.INNOVATIONS

ROSENBAUER SPRINKLER-APP

Get our Sprinkler-App! A useful tool to evaluate dimensions of sprinkler systems.

MASTERCONTROL

Subtantial reduction of operating costs with automated sprinkler system inspections.